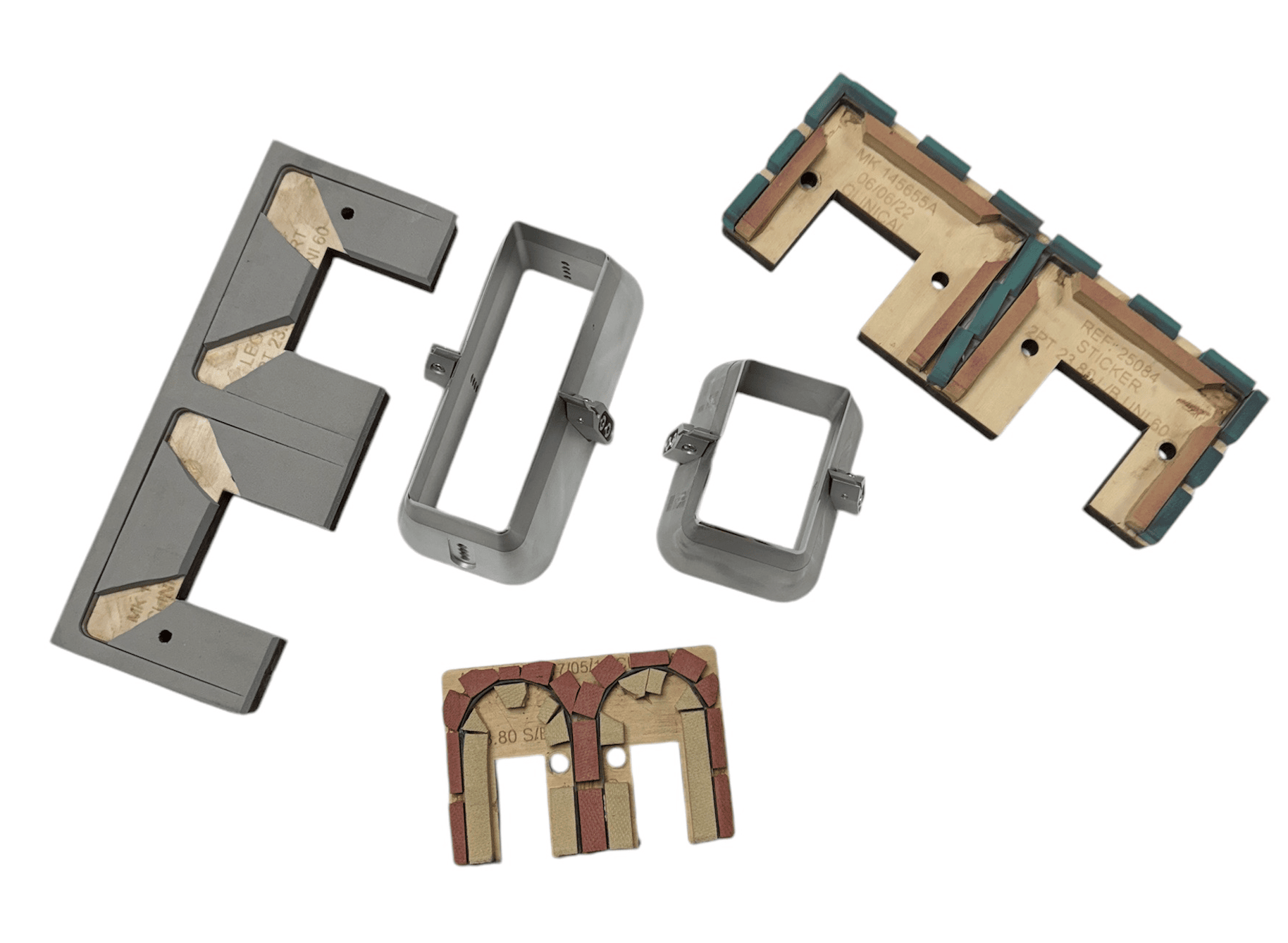

Die Cutting and Ram Punching

Precision Cuts for Your Business Needs

Miniature Die Cutting

Our in-line die cutting units work seamlessly alongside stitching and folding machines, ensuring a smooth, automated workflow. This brings consistent, high-quality results at cost-effective prices. We can handle various designs from basic round corners to complex leaflet shapes. We also handle standard A5 and A4 sizes while bringing out the best in miniature formats.

We use unique dies from your artwork, producing clean, individual punches for booklets or leaflets while minimising nicks and defects for a professional brand appearance. Also, we have an offline die cutting service utilising the same precise processes, which could be a cost-effective alternative for your project.

High quality

products

Single automated process

Reliable &

trusted

Ram Punching

We offer cost-effective Ram punching as an alternative to traditional die cutting. Ram punching excels at creating clean, precise cuts for a variety of simple shapes, making it perfect for projects such as Business cards, Tickets, Playing cards, Wet labels, Swing tags and Vouchers.

We also ram punch to achieve radius corners on Z Fold Card covers.

We have dies for all standard Z Fold Card sizes (85 x 54mm & 108 x 78mm), ensuring a perfect fit for your project.

Ram punching employs a continuous blade, which helps in cleaner cuts with minimal imperfections, leaving no nicks on your finished products.

Ram punching is a cost-effective, efficient solution for projects requiring simple shapes. Its continuous blade allows for high-speed production, meeting tight deadlines, and delivering superior edge quality.

Cost

effective

Precise & clean cuts

Different design

options

High speed

production

Get Your Sample

If you would like to receive one of our sample packs, please click on the link below and fill in your contact information.

Notable Service Features

Efficient single-step process

Die cutting is completed in a streamlined, automated process

Expert offline die cutting

Alternative process for finished booklets and leaflets.

Smooth, no-nick edges

Continuous blade dies ensure clean, polished edges

How our die cutting works

Designer Collaboration

Die Fabrication

Flawless Punching Process

Shape Your Ideas with Precision

Make use of our cutting-edge equipment to produce unique, superior finishes for pamphlets, booklets, cards, and more. Give our helpful staff a call or get a sample pack to discuss your project right now!